Opinion

Opinion

In Defense of Blue Hydrogen: Navigating the Nuances in the Pursuit of a Sustainable Future

In Defense of Blue Hydrogen: Navigating the Nuances in the Pursuit of a Sustainable Future

Zach Foss

Zach Foss

Jan 30, 2024

Jan 30, 2024

As the world grapples with the need to transition to low-carbon energy sources, the debate over the viability of blue hydrogen – hydrogen gas produced through steam methane reforming (SMR) combined with carbon capture and storage (CCUS) - has intensified. Recent critiques have cast doubt on the environmental benefits of blue hydrogen, with some going as far as to argue that it is more carbonintensive than its grey hydrogen counterpart (SMR with no CCUS). [1] However, a closer examination of key factors reveals that dismissing the benefits of blue hydrogen would be premature. In simpler terms – don’t throw the baby out with the bathwater.

Understanding Grey Hydrogen's Current Role:

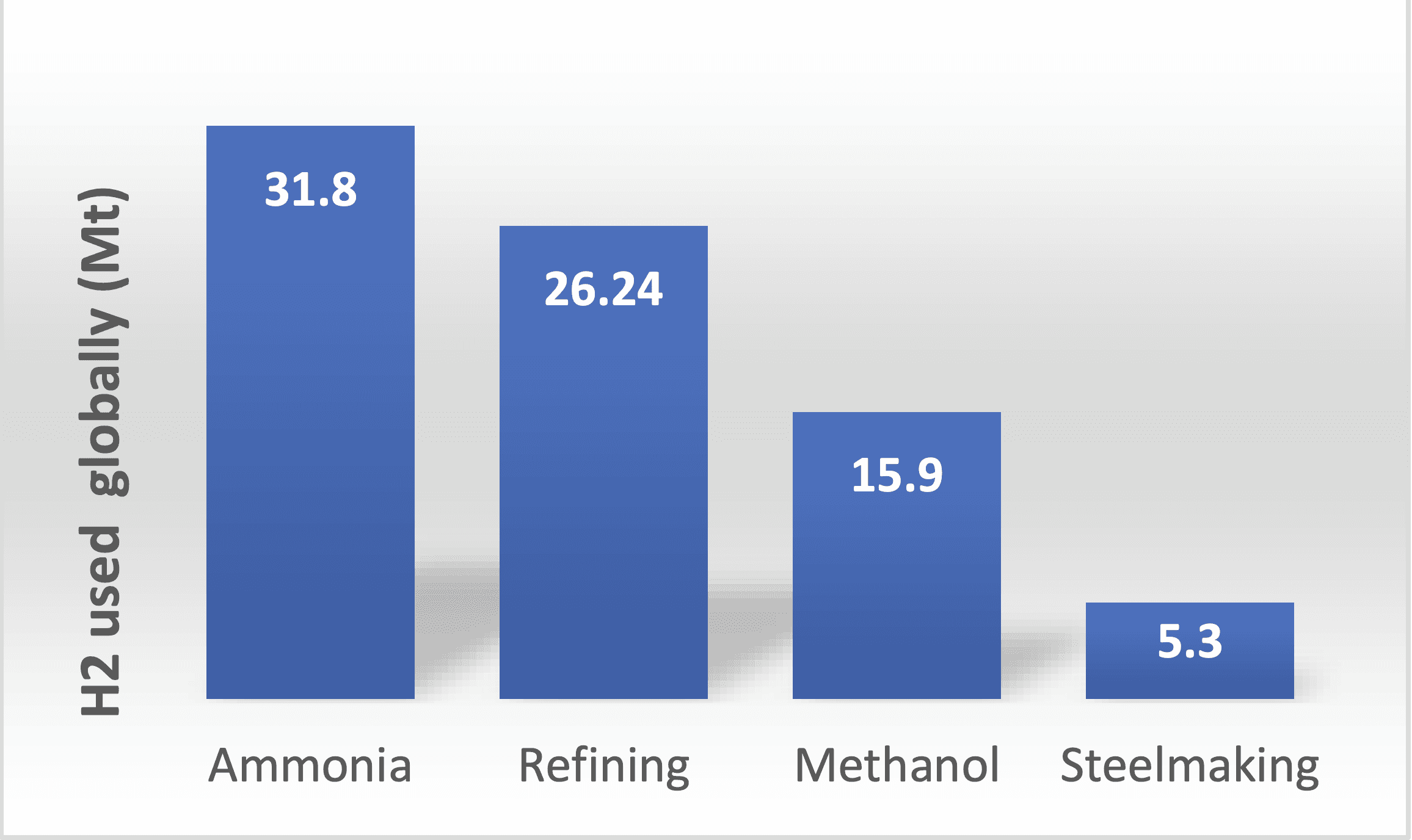

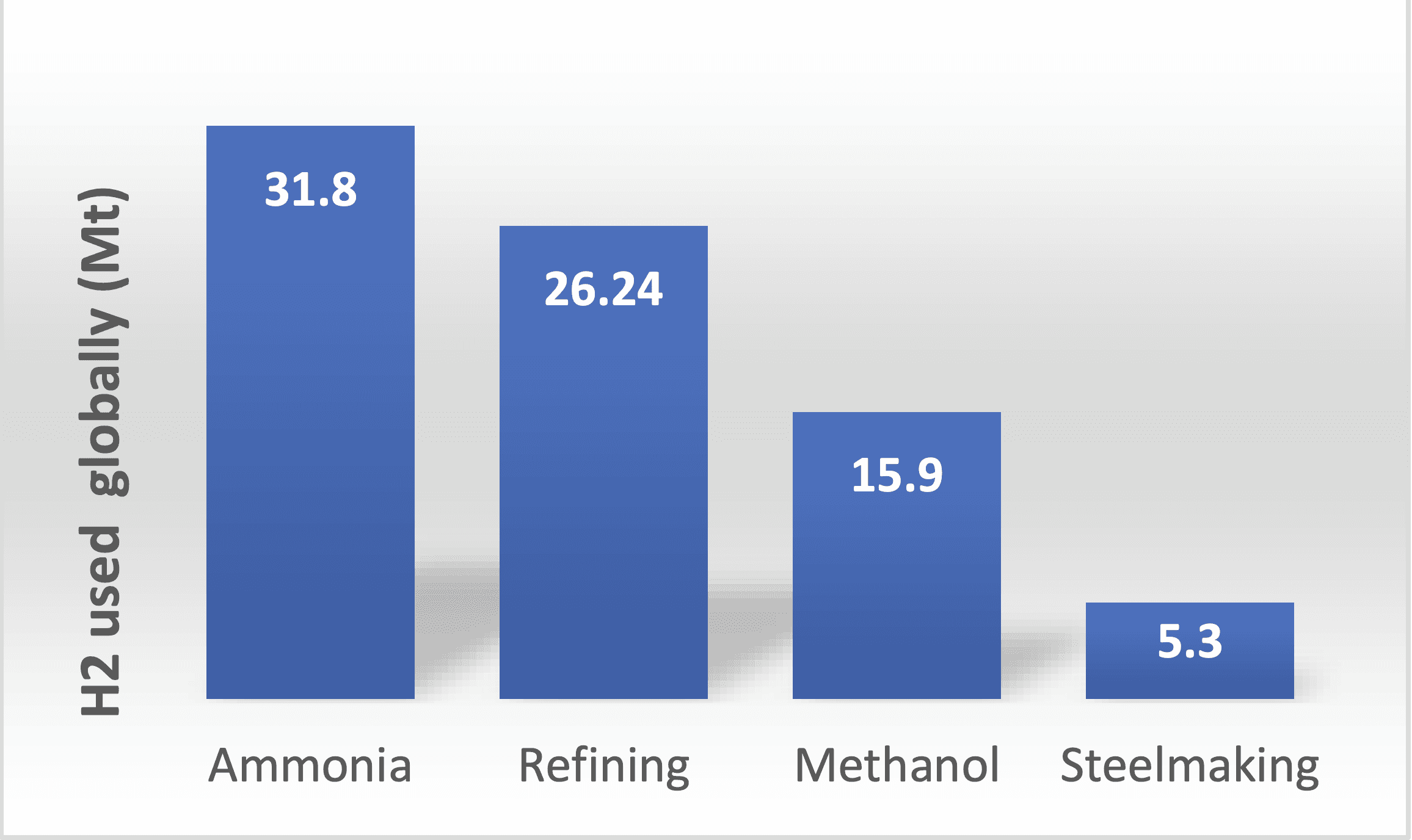

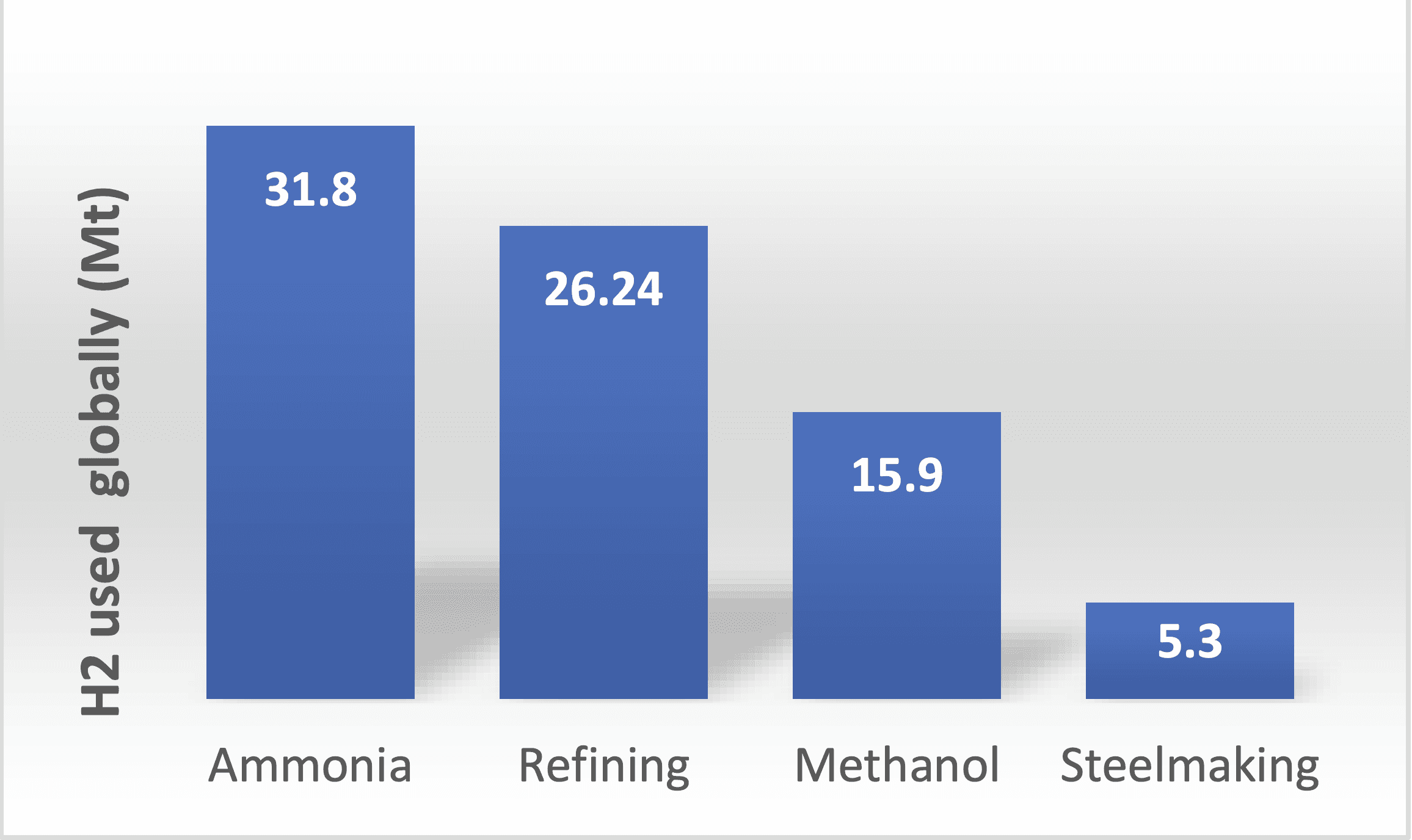

Grey hydrogen, produced through conventional SMR without CCUS, plays a massive role in various industries - including oil refining, ammonia & methanol production, steelmaking, and concrete production. In 2022, these industries globally required over 94 Mt of hydrogen product, and less than 1% of this H2 was produced as low-emission hydrogen. This low-emission hydrogen production needs to grow more than 100x by 2030 to be in line with the “Net Zero Emissions by 2050” (NZE)scenario. All told, existing global hydrogen production accounts for between 920-1060 Mt of CO2 emissions per year, or roughly the same carbon footprint as the entire global aviation industry. [2]

Figure 1. Hydrogen Usage in Different Industries

The stark reality is that these sectors are unlikely to transition rapidly to fully renewable hydrogen. There is significant infrastructure dedicated to grey hydrogen that would have no use as we transition to electrolysis/green hydrogen production methods. It is much more feasible in the near term (2-3 decades) to combine these existing grey hydrogen assets with CCUS technology – converting them from grey to blue hydrogen producers - to drastically reduce the carbon emissions from current hydrogen needs. This is similar to what has been done with coal power generation across the globe – leveraging existing boiler assets and converting them to natural gas or utilizing CCUS technologies to directly capture CO2 from flue gas streams – to reduce the CO2 footprint of that electricity source, rather than just idling/abandoning the existing equipment. [3] In the US alone, 121 coalfired power plants were repurposed to burn other types of fuels from 2011 to 2019 – 103 of which went to natural gas. [4]

A blue hydrogen strategy of just 60% CO2 capture would result in up to 640 Mt of carbon emission abatement – a capture percentage that has already been demonstrated at commercial scale and requires only pre-combustion CCUS technology – equivalent to the CO2 footprint of over 138 million passenger vehicles. An argument can be made that up to 92% CO2 capture rates are possible when post combustion capture of the flue gas is included [5], and up to 99% is possible with newer technologies like autothermal reforming which eliminates the flue gas stream. [6; 7]

The Electrolysis Challenge:

Many of the detractors of blue hydrogen are proponents of transitioning directly to green 31.8 26.24 15.9 5.3 Ammonia Refining Methanol Steelmaking H2 used globally (Mt) hydrogen. While green hydrogen - produced through electrolysis of water using renewable energy - is an appealing prospect, scaling up electrolysis to meet global hydrogen demand poses considerable challenges. The sheer magnitude of current hydrogen usage in multiple industries and the difficulty of rapidly replacing existing grey hydrogen infrastructure make blue hydrogen a more pragmatic choice in the near term.

Electrolysis requires ~50 kWh of electricity to produce a single kg of hydrogen. [8] For the hydrogen produced from electrolysis to be “green”, this 50 kWh/kg must come directly from renewable energy sources – like wind, solar, or hydro. By comparison, the SMR reaction is endothermic and requires roughly the same energy input (44.5 kWh/kg) [9], but this energy can come from directly burning a portion of the natural gas feed to the reactor. Little to no additional electricity production is needed. This energy requirement does not change significantly when converting from grey to blue hydrogen either. To implement 60% CO2 capture, the energy required per kg of H2 produced only increases by 1-2%. For 93% capture, we see a 10-12% increase in energy required, though this is still below the energy threshold for electrolysis produced H2. [9]

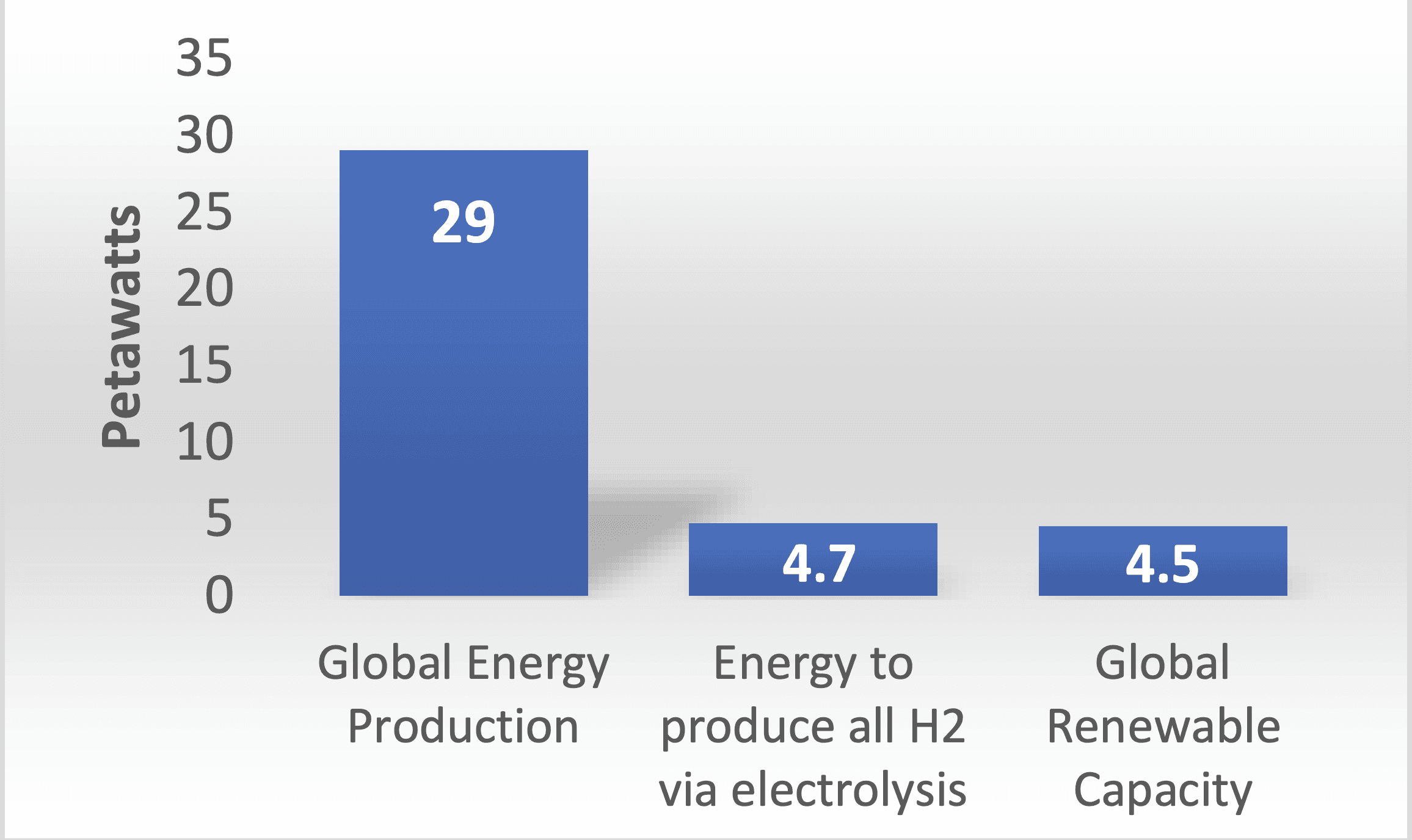

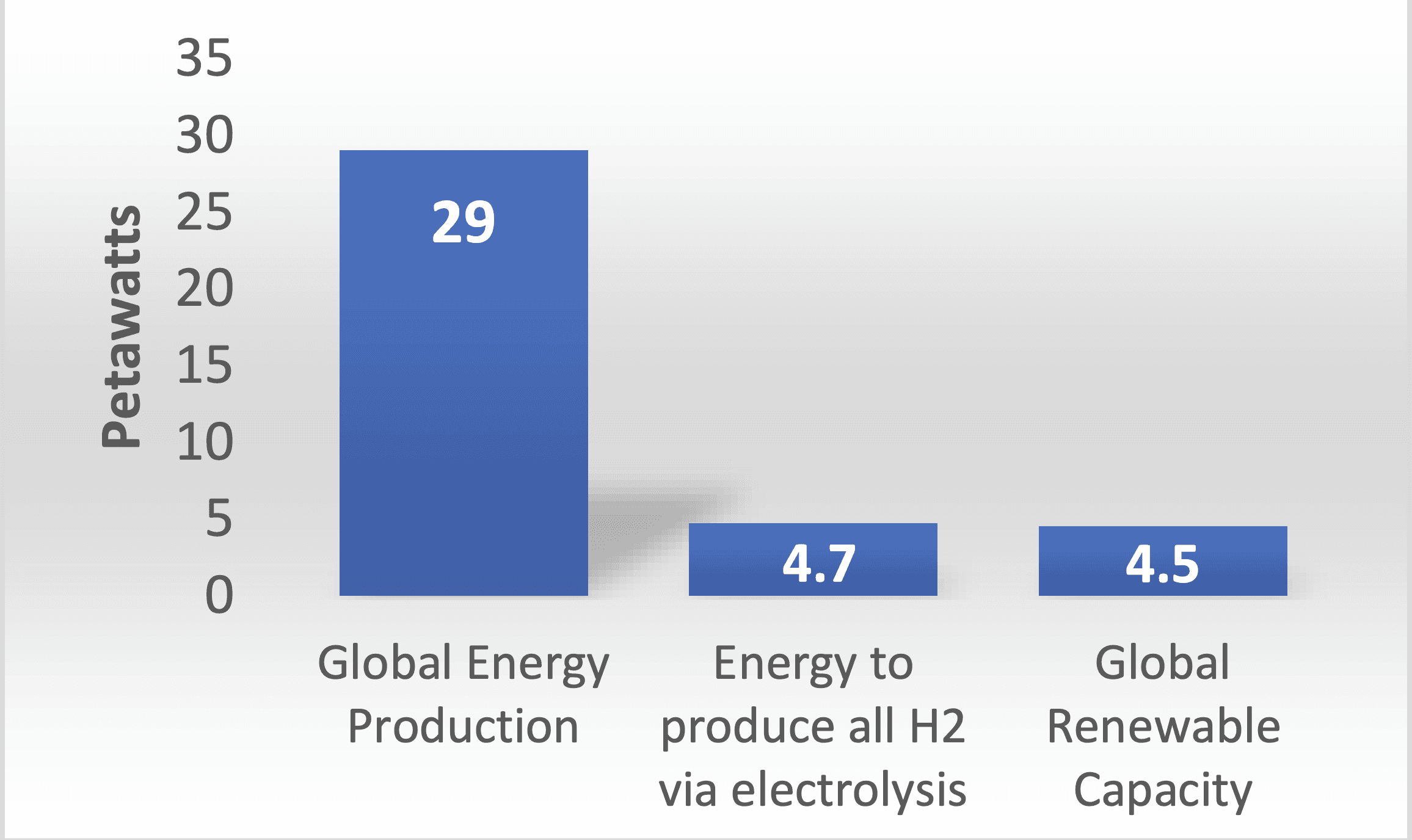

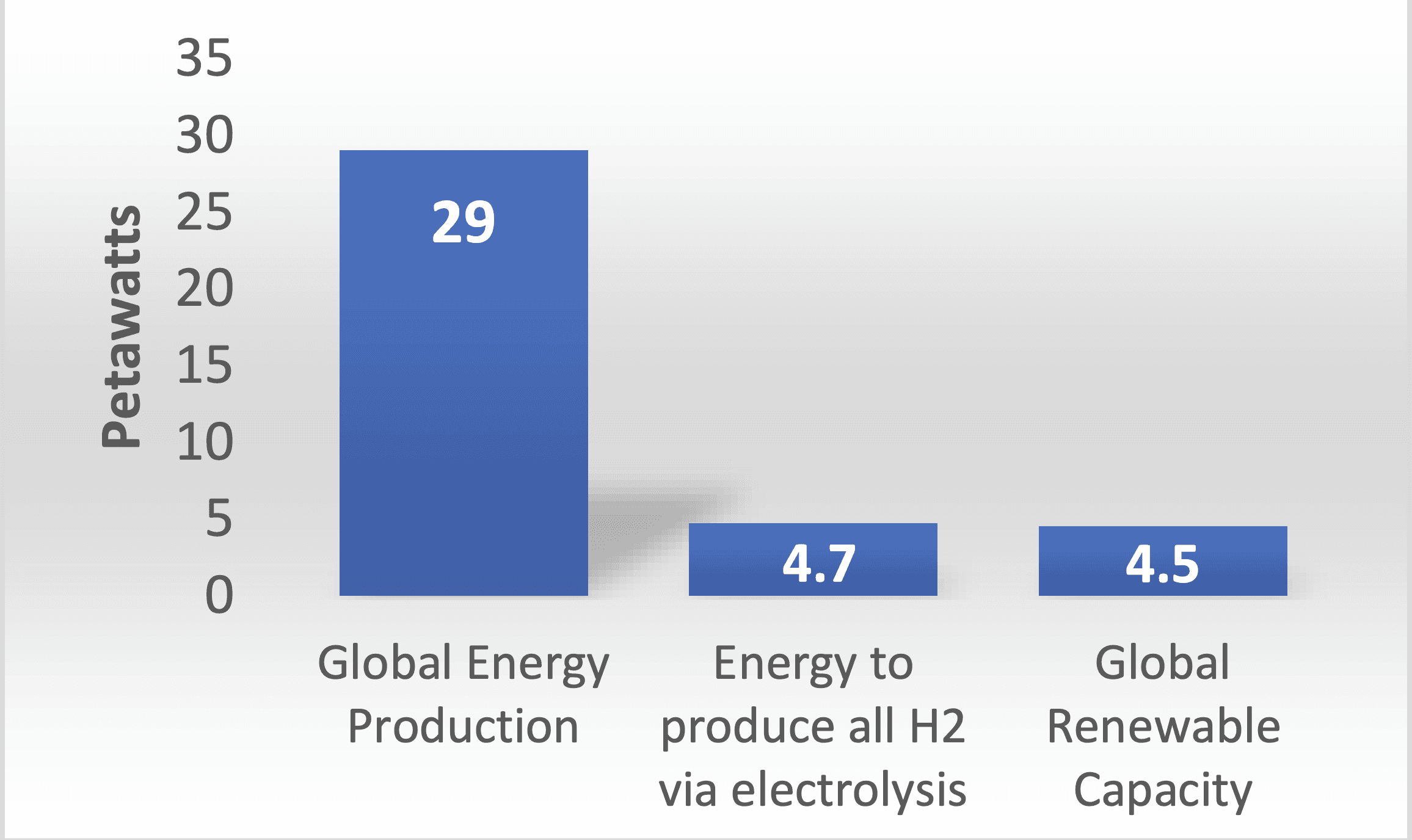

To demonstrate how far we are from 100% replacement of today’s hydrogen needs with green hydrogen, we can look at global energy production - both total and renewable:

Figure 2. Global Energy Production, Renewables, and Required Energy for Green Hydrogen [7; 8]

According to the International Energy Agency (IEA), global renewable energy capacity will be roughly 4500 TW for 2024. [10] Even if 100% of global renewable energy was redirected to producing green hydrogen, we would still be 200 TW short – and that is without considering the significant increases in global hydrogen demand that will be needed to decarbonize other hard to-abate industries such as steel, aviation, and long-haul transportation.

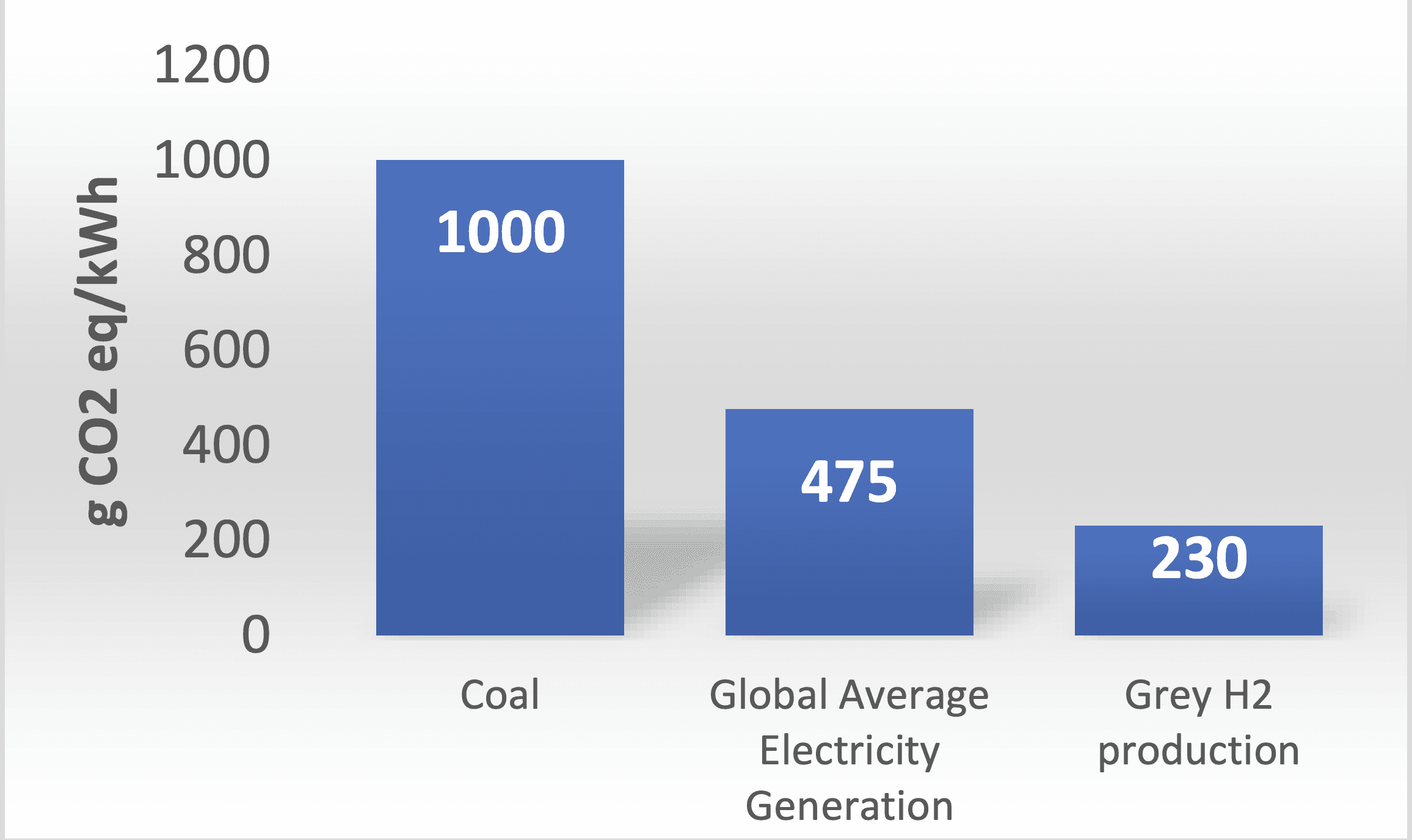

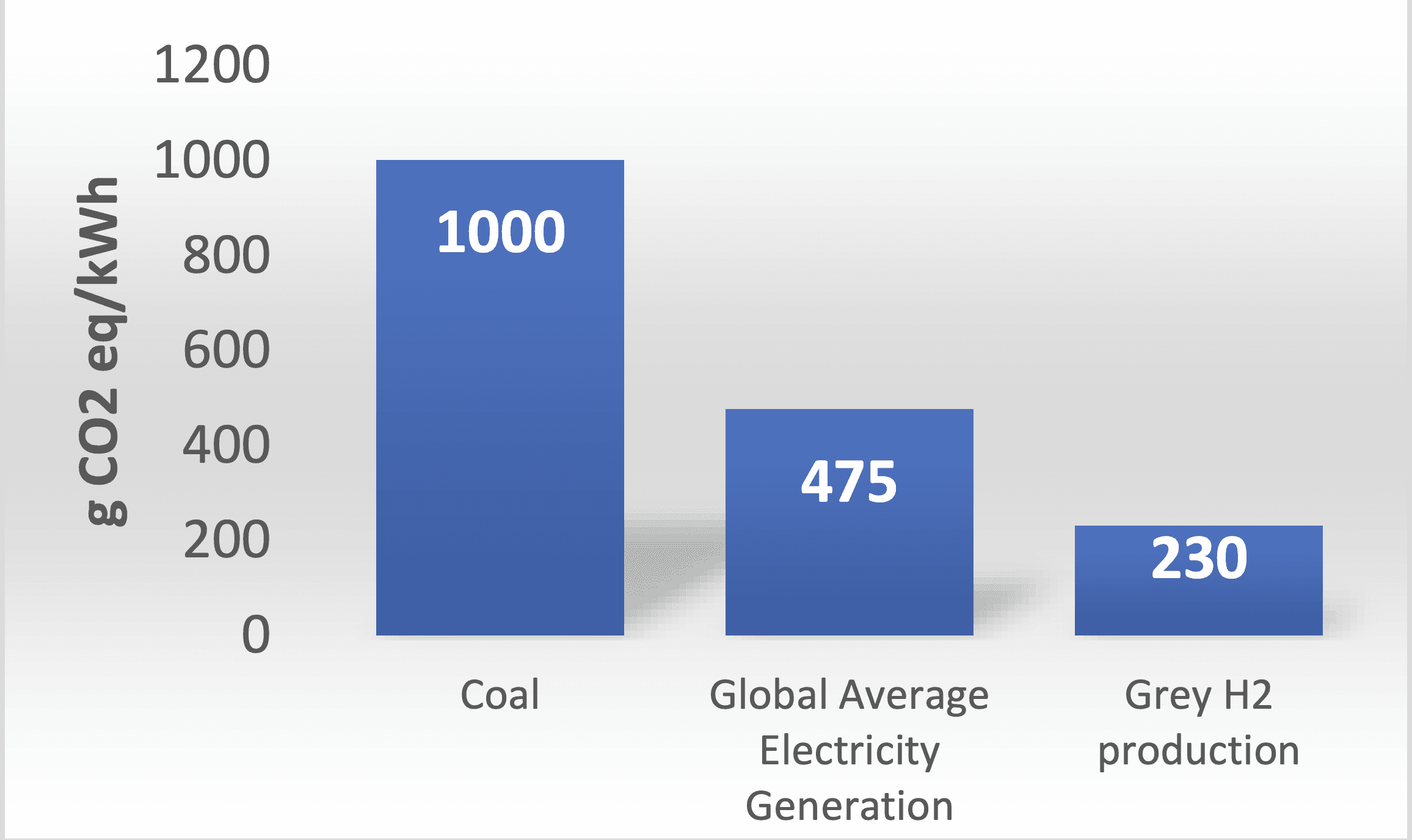

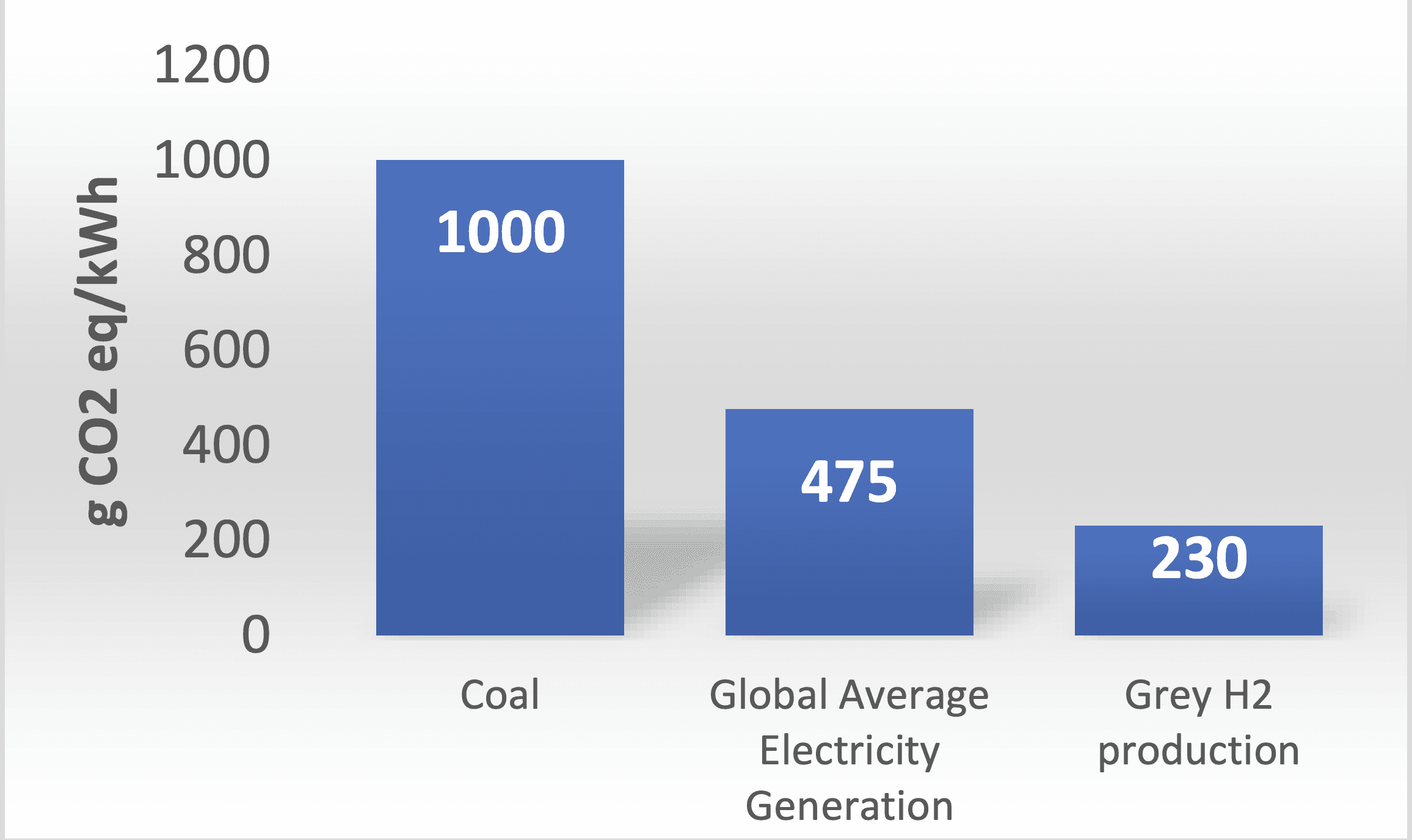

As the final point to the electrolysis challenge: globally we are currently adding between 300- 500 TW of renewable energy capacity each year. [12] For these new renewable energy sources, will replacing existing grey H2 generation with renewable electrolysis be the largest carbon abatement opportunity? The carbon footprint of each kg of hydrogen produced today is roughly 11.3 kg CO2 equivalent. [13] Based on electrolysis energy requirements, each kWh of renewable power towards green hydrogen therefore abates ~230 g CO2eq. If we compare this to the global average for all energy production, we can see that this additional renewable green capacity is better applied to offsetting existing electricity generation than it would be applied to replacing grey/blue H2 production [9; 14]:

Figure 3. Potential Abatement per kWh Renewables

Based on this data – the best use of additional renewable capacity from a carbon abatement standpoint would be to tackle other existing heavy carbon emitting power generation prior to replacing grey H2 production. This is not to say that grey hydrogen production does not need to be tackled – only that it would be more prudent to convert existing grey assets to blue, while utilizing our current and future renewable assets to offsetting other heavier CO2 sources.

Advancements in CCUS and Fugitive Methane Emission Technologies:

Arguments against blue hydrogen point out the large impacts of both fugitive methane emissions (natural gas leaks from production to utilization), as well as the unpredictability of CCUS storage methods. While it is important to acknowledge the concerns raised about both, it is also crucial to highlight the ongoing advancements in these technologies. Continuous research and development efforts are improving the efficacy of CCUS, ensuring a higher percentage of carbon is captured and stored. There are already existing markets for carbon sequestration – such as Enhanced Oil Recovery (EOR) where CO2 gas is injected into a well and can act as a solvent to release oil and gas from rock strata and flush them to the well head. Additional CCUS technologies are being developed that don’t contribute to increases in oil & gas production – such as permanent underground sequestration, utilizing CO2 as a feedstock for manufacturing synthetic fuels, permanently capturing CO2 as a solid in concrete materials, plastics/chemicals manufacturing from CO2 feedstocks, solid precipitation as calcium carbonite, and microalgae production. All these technologies are still fairly new, but CCUS technology improvement is a must if humanity is to reach Net Zero by 2050. [15]

fugitive methane emissions contribute to minimizing environmental impact. Many detractors of blue hydrogen production rightly point out that methane itself is a potent greenhouse gas – and the benefits of blue hydrogen production can be squandered if enough methane is released during its production, storage, and transportation. [1] Technologies enabling industry to monitor and correct these emissions, as well as government monitoring for regulatory & compliance purposes, will be crucial. It is estimated that at least 50% of global fugitive methane emissions from natural gas activities could be saved by using technologies and approaches that would pay for themselves just based on the recovery of the methane. [16] Without any other incentives – if provided with the right tools and technologies - there is economic motivation for industry to recapture this lost methane. Other technologies have already led to drastic improvements in monitoring fugitive emissions, including optical gas imaging cameras, aerial monitoring (aircraft, methane balloon, and drone/UAV), and satellite monitoring. [17] These technologies can and should be leveraged to implement transparency and reporting requirements for methane emissions, and potentially future taxes/quotas to ensure proper incentives for methane emissions reduction. Since fugitive methane emissions are one of the largest arguments against blue hydrogen, any improvements in this area increases the argument for conversion.

Reassessing Global Warming Potential (GWP) Time Horizon:

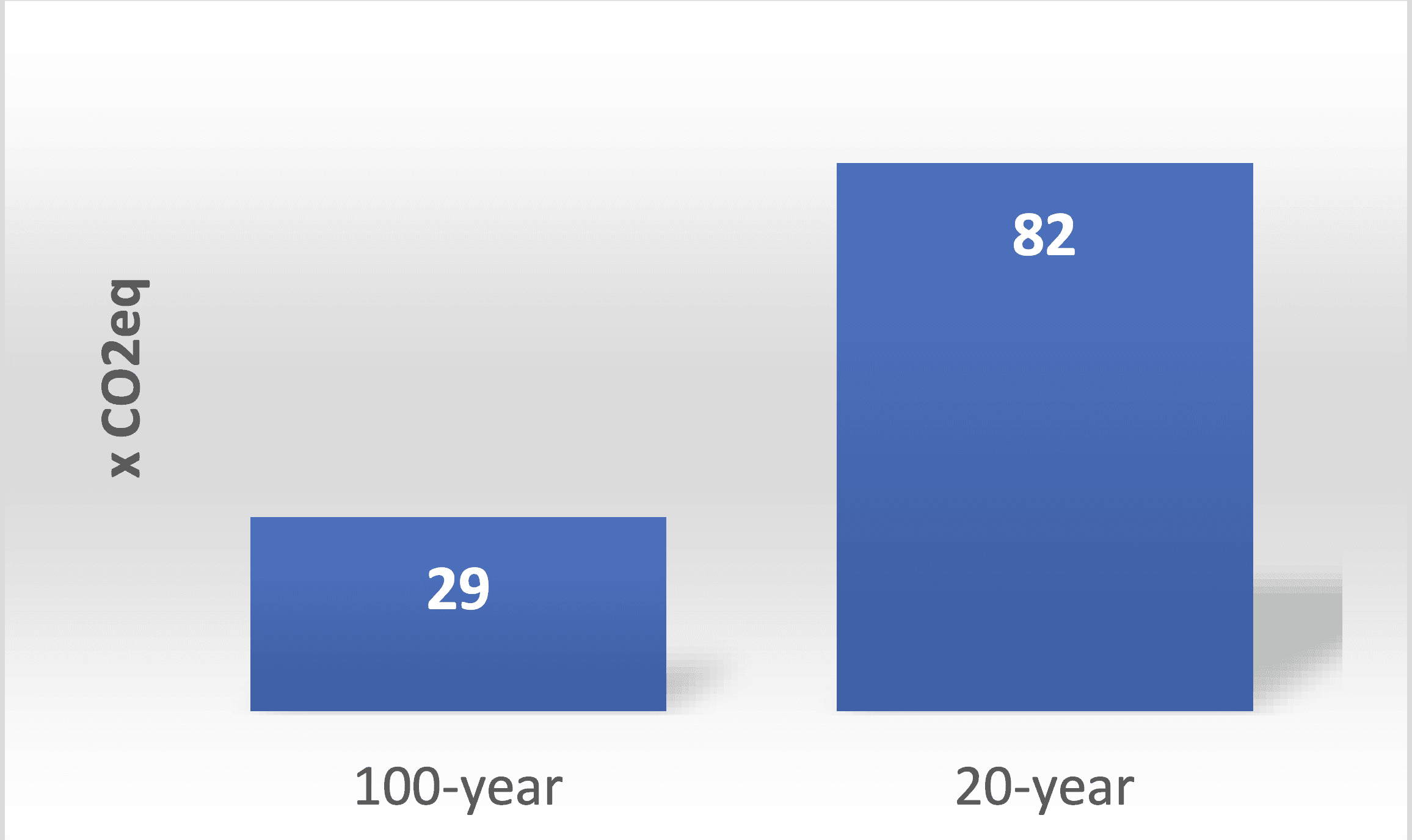

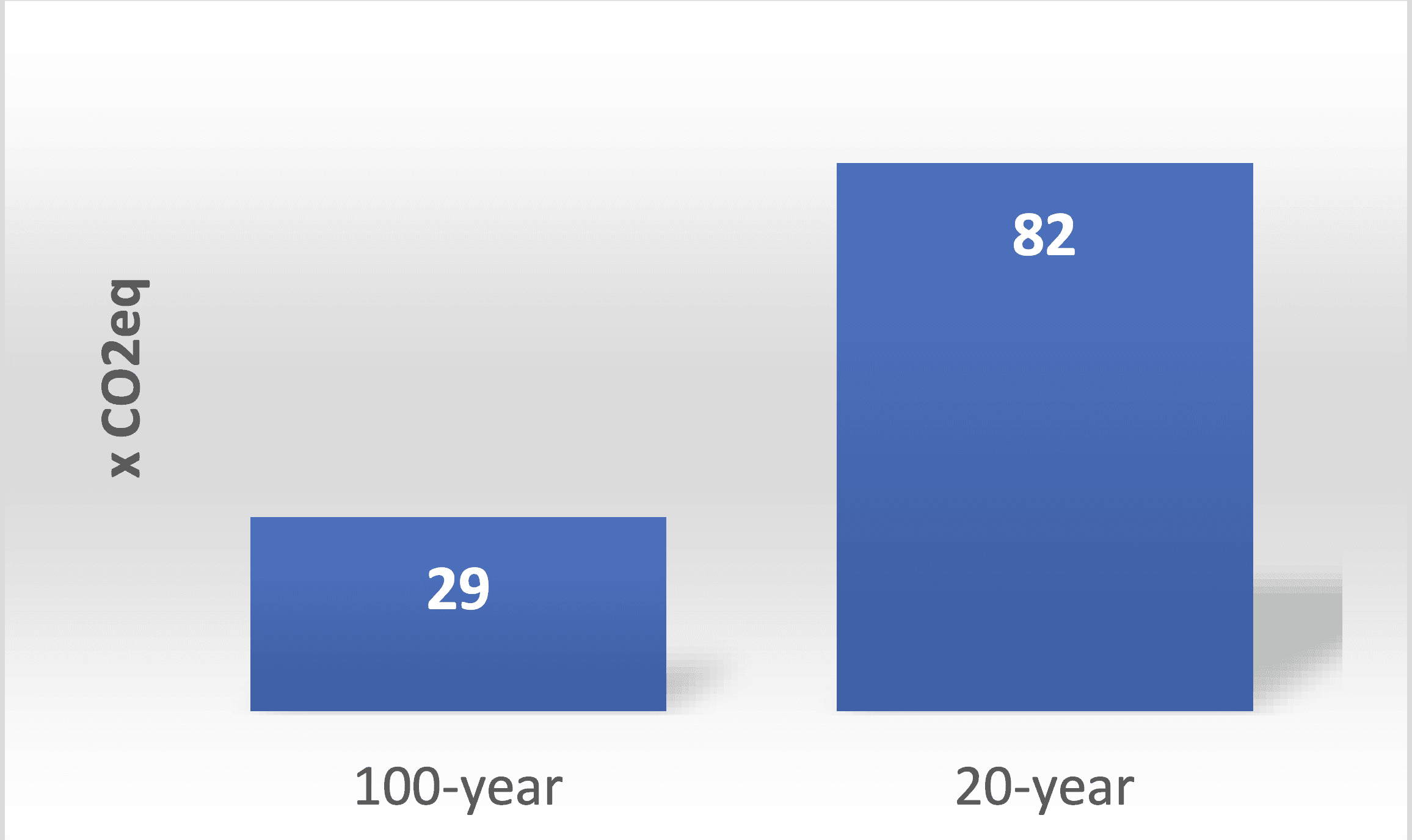

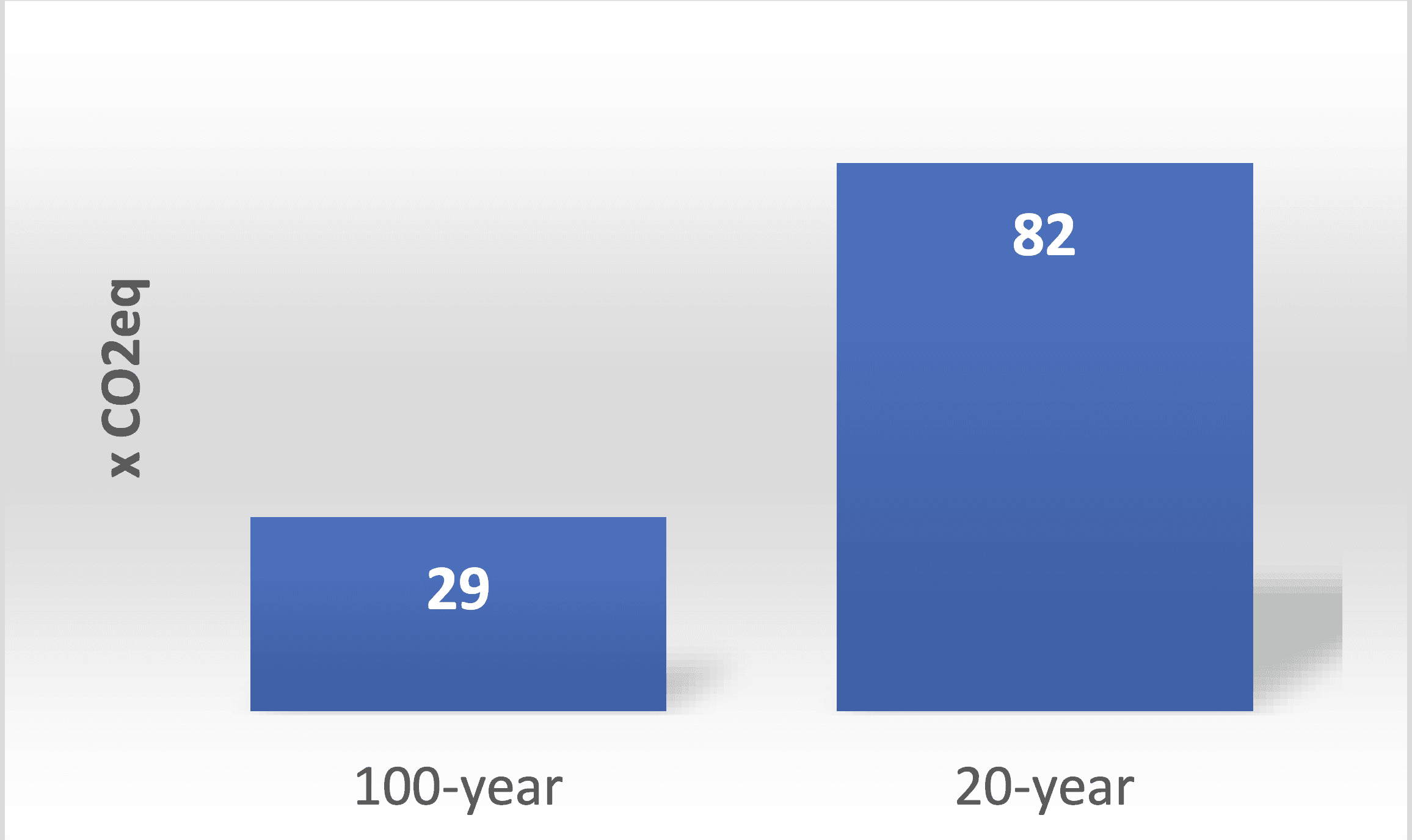

One aspect often overlooked in the conversation surrounding blue hydrogen is the choice of the time horizon for GWP, or Global Warming Potential, assessment. GWP allows emission impacts from different gases to be standardized to an “equivalent CO2” unit. Many of the recent analyses of blue hydrogen focus on a 20-year GWP calculation rather than the standard 100- year. This, combined with assumptions like 3.5% fugitive emissions, immediately put any technology leveraging natural gas at a significant disadvantage. Methane, a potent but short-lived greenhouse gas, does not linger in the atmosphere as long as carbon dioxide – therefore the shorter time horizon stacks the deck significantly against it.

There are two important reasons to look at a 100-year GWP instead – or to at least consider both. First, it is the most well-known and widely used metric - baked into policies, international agreements, and greenhouse gas reporting requirements. [18] It is therefore most likely to be utilized in any future legislation around carbon control. Second, 100 years is a much more reasonable time frame for humanity to achieve a fully carbon neutral/negative energy and manufacturing system than 20 years. Despite many countries and companies pledging a goal of Net Zero by 2050, humanity is currently not on course to meet this objective. [19] A 100-year GWP will therefore be better able to capture the effects of methane produced today over the course of humanity’s path to a carbon neutral future.

Evaluations of blue vs. grey vs. green hydrogen that a) do not consider the potential (and likely) future fugitive methane emissions reductions, and b) look only at a 20-year GWP analysis of methane, are stacking the deck against any technology that leverages natural gas. This includes 99% of existing hydrogen manufacturing capacity today, which cannot be easily or quickly converted to renewable H2 production.

Figure 4. GWP Comparison for Methane

Renewable and Low-Carbon Driving Forces:

One final often-overlooked advantage of blue hydrogen lies in its flexibility regarding energy sources. As described above – new renewable and low-carbon energy assets are currently put to better use offsetting existing electricity generation than offsetting hydrogen production via electrolysis – but this will not always be the case. As the global electricity grid is decarbonized over the coming decades, eventually hydrogen production will be the lowest hanging fruit, and it will make sense to apply low-carbon electricity to offset current production. With blue hydrogen, there are areas where this new renewable electricity can be used, including energy requirements for separating and purifying captured CO2, and CO2 compression. This further improves the CO2 footprint of blue hydrogen over grey, giving us additional time to build up electrolysis assets and expertise to continue to decarbonize the hydrogen market.

Conclusion:

In the pursuit of a sustainable future, it is crucial that we avoid dismissing viable solutions without a comprehensive assessment. Blue hydrogen, when produced with improved CCUS and fugitive methane emission technologies, coupled with a careful consideration of GWP values and the use of renewable or low-carbon energy sources, can serve as a vital stepping-stone in our transition to a low-carbon economy. While not a panacea, blue hydrogen contributes meaningfully to our collective efforts to mitigate climate change while electrolysis capacity and renewable energy resources continue to grow. As we navigate the complex terrain of the energy transition, a balanced and nuanced approach that considers the realities of current industries, technological advancements, and the urgency of the climate crisis will be key to shaping a sustainable hydrogen future.

References:

[1] How green is blue hydrogen? Howarth RW, Jacobson MZ. 2021, Energy Sci Eng., pp. 1676-1687.

[2] International Energy Agency. Global Hydrogen Review 2022. 2022.

[3] Badamasi, Hamza. earth.org. [Online] December 2, 2020. [Cited: January 14, 2023.] https://earth.org/data_visualization/the-coal-to-naturalgas-transition-is-saving-lives/.

[4] U.S. Energy Information Administration. Today in Energy. eia.gov. [Online] August 5, 2020. [Cited: Jan 24, 2024.] https://www.eia.gov/todayinenergy/detail.php?id=44636# :~:text=According%20to%20data%20from%20the,by%20na tural%20gas%2Dfired%20plants..

[5] Comparative assessment of blue hydrogen from steam methane reforming, autothermal reforming, and natural gas decomposition technologies for natural gas-producing regions. A.O. Oni, K. Anaya, T. Giwa, G. Di Lullo, A. Kumar. 115245, s.l. : Energy Conversion and Management, 2022, Vol. 254. ISSN 0196-8904.

[6] Shell. shell.com. Blue Hydrogen Production. [Online] 2023. [Cited: Jan 24, 2024.] https://www.shell.com/business-customers/catalyststechnologies/licensed-technologies/refinerytechnology/shell-blue-hydrogen-process.html.

[7] Hockey, Mike. Honeywell Performance Materials and Technologies. pmt.honeywell.com. [Online] [Cited: January 24, 2024.] https://pmt.honeywell.com/us/en/aboutpmt/newsroom/press-release/2022/05/cvr-energysubsidiary-selects-honeywell-for-a-lower-carbon-hydrogenstudy-at-coffeyvillesite#:~:text=Depending%20on%20the%20inlet%20gas,incr easing%20high%2Dpurity%20hydrogen%20recov.

[8] Blain, Loz. Record-breaking hydrogen electrolyzer claims 95% efficiency. [Online] New Atlas, March 16, 2022. [Cited: January 14, 2024.] https://newatlas.com/energy/hysataefficient-hydrogen-electrolysis/.

[9] IEA. Comparison of the emissions intensity of different hydrogen production routes. iea.org. [Online] June 29, 2023. [Cited: January 14, 2024.] https://www.iea.org/dataand-statistics/charts/comparison-of-the-emissionsintensity-of-different-hydrogen-production-routes-2021.

[10] IEA. Renewable Energy Market Update - June 2023. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energy-marketupdate-june-2023/executive-summary.

[11] Ember. ember-climate.org. Yearly electricity data. [Online] January 23, 2024. [Cited: January 24, 2024.] https://ember-climate.org/data-catalogue/yearlyelectricity-data/.

[12] IEA. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energymarket-update-june-2023/executive-summary.

[13] IEA. iea.org. Towards hydrogen definitions based on their emissions intensity. [Online] 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/towards-hydrogendefinitions-based-on-their-emissions-intensity/executivesummary.

[14] Global Energy & CO2 Status Report 2019. IEA. Paris : IEA, 2019.

[15] Lebling, Katie, et al. World Resources Institute. [Online] November 13, 2023. [Cited: January 14, 2024.] https://www.wri.org/insights/carbon-capturetechnology#:~:text=The%202023%20IEA%20Roadmap%20 to,mitigation%20of%20energy%20sector%20emissions..

[16] European Commission - Fugitive Methane Emissions. commission.europa.eu. [Online] June 2020. [Cited: January 14, 2024.] https://commission.europa.eu/system/files/2020- 06/speaker_intervention_- _european_university_institute.pdf.

[17] Exxonmobil press release. ExxonMobil field testing new comprehensive methane monitoring technologies. corporate.exxonmobil.com. [Online] April 9, 2020. [Cited: January 14, 2024.] https://corporate.exxonmobil.com/news/newsreleases/2020/0409_exxonmobil-field-testing-newcomprehensive-methane-monitoring-technologies.

[18] Ocko, Ilissa B and Hamburg, Steven P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. [Online] July 20, 2022. [Cited: January 14, 2024.] https://doi.org/10.5194/acp-22-9349-2022. 9349-9368.

[19] United Nations. un.org. For a livable climate: Net-zero commitments must be backed by credible action. [Online] [Cited: January 24, 2024.] https://www.un.org/en/climatechange/net-zerocoalition#:~:text=Are%20we%20on%20track%20to,short% 20of%20what%20is%20required..

As the world grapples with the need to transition to low-carbon energy sources, the debate over the viability of blue hydrogen – hydrogen gas produced through steam methane reforming (SMR) combined with carbon capture and storage (CCUS) - has intensified. Recent critiques have cast doubt on the environmental benefits of blue hydrogen, with some going as far as to argue that it is more carbonintensive than its grey hydrogen counterpart (SMR with no CCUS). [1] However, a closer examination of key factors reveals that dismissing the benefits of blue hydrogen would be premature. In simpler terms – don’t throw the baby out with the bathwater.

Understanding Grey Hydrogen's Current Role:

Grey hydrogen, produced through conventional SMR without CCUS, plays a massive role in various industries - including oil refining, ammonia & methanol production, steelmaking, and concrete production. In 2022, these industries globally required over 94 Mt of hydrogen product, and less than 1% of this H2 was produced as low-emission hydrogen. This low-emission hydrogen production needs to grow more than 100x by 2030 to be in line with the “Net Zero Emissions by 2050” (NZE)scenario. All told, existing global hydrogen production accounts for between 920-1060 Mt of CO2 emissions per year, or roughly the same carbon footprint as the entire global aviation industry. [2]

Figure 1. Hydrogen Usage in Different Industries

The stark reality is that these sectors are unlikely to transition rapidly to fully renewable hydrogen. There is significant infrastructure dedicated to grey hydrogen that would have no use as we transition to electrolysis/green hydrogen production methods. It is much more feasible in the near term (2-3 decades) to combine these existing grey hydrogen assets with CCUS technology – converting them from grey to blue hydrogen producers - to drastically reduce the carbon emissions from current hydrogen needs. This is similar to what has been done with coal power generation across the globe – leveraging existing boiler assets and converting them to natural gas or utilizing CCUS technologies to directly capture CO2 from flue gas streams – to reduce the CO2 footprint of that electricity source, rather than just idling/abandoning the existing equipment. [3] In the US alone, 121 coalfired power plants were repurposed to burn other types of fuels from 2011 to 2019 – 103 of which went to natural gas. [4]

A blue hydrogen strategy of just 60% CO2 capture would result in up to 640 Mt of carbon emission abatement – a capture percentage that has already been demonstrated at commercial scale and requires only pre-combustion CCUS technology – equivalent to the CO2 footprint of over 138 million passenger vehicles. An argument can be made that up to 92% CO2 capture rates are possible when post combustion capture of the flue gas is included [5], and up to 99% is possible with newer technologies like autothermal reforming which eliminates the flue gas stream. [6; 7]

The Electrolysis Challenge:

Many of the detractors of blue hydrogen are proponents of transitioning directly to green 31.8 26.24 15.9 5.3 Ammonia Refining Methanol Steelmaking H2 used globally (Mt) hydrogen. While green hydrogen - produced through electrolysis of water using renewable energy - is an appealing prospect, scaling up electrolysis to meet global hydrogen demand poses considerable challenges. The sheer magnitude of current hydrogen usage in multiple industries and the difficulty of rapidly replacing existing grey hydrogen infrastructure make blue hydrogen a more pragmatic choice in the near term.

Electrolysis requires ~50 kWh of electricity to produce a single kg of hydrogen. [8] For the hydrogen produced from electrolysis to be “green”, this 50 kWh/kg must come directly from renewable energy sources – like wind, solar, or hydro. By comparison, the SMR reaction is endothermic and requires roughly the same energy input (44.5 kWh/kg) [9], but this energy can come from directly burning a portion of the natural gas feed to the reactor. Little to no additional electricity production is needed. This energy requirement does not change significantly when converting from grey to blue hydrogen either. To implement 60% CO2 capture, the energy required per kg of H2 produced only increases by 1-2%. For 93% capture, we see a 10-12% increase in energy required, though this is still below the energy threshold for electrolysis produced H2. [9]

To demonstrate how far we are from 100% replacement of today’s hydrogen needs with green hydrogen, we can look at global energy production - both total and renewable:

Figure 2. Global Energy Production, Renewables, and Required Energy for Green Hydrogen [7; 8]

According to the International Energy Agency (IEA), global renewable energy capacity will be roughly 4500 TW for 2024. [10] Even if 100% of global renewable energy was redirected to producing green hydrogen, we would still be 200 TW short – and that is without considering the significant increases in global hydrogen demand that will be needed to decarbonize other hard to-abate industries such as steel, aviation, and long-haul transportation.

As the final point to the electrolysis challenge: globally we are currently adding between 300- 500 TW of renewable energy capacity each year. [12] For these new renewable energy sources, will replacing existing grey H2 generation with renewable electrolysis be the largest carbon abatement opportunity? The carbon footprint of each kg of hydrogen produced today is roughly 11.3 kg CO2 equivalent. [13] Based on electrolysis energy requirements, each kWh of renewable power towards green hydrogen therefore abates ~230 g CO2eq. If we compare this to the global average for all energy production, we can see that this additional renewable green capacity is better applied to offsetting existing electricity generation than it would be applied to replacing grey/blue H2 production [9; 14]:

Figure 3. Potential Abatement per kWh Renewables

Based on this data – the best use of additional renewable capacity from a carbon abatement standpoint would be to tackle other existing heavy carbon emitting power generation prior to replacing grey H2 production. This is not to say that grey hydrogen production does not need to be tackled – only that it would be more prudent to convert existing grey assets to blue, while utilizing our current and future renewable assets to offsetting other heavier CO2 sources.

Advancements in CCUS and Fugitive Methane Emission Technologies:

Arguments against blue hydrogen point out the large impacts of both fugitive methane emissions (natural gas leaks from production to utilization), as well as the unpredictability of CCUS storage methods. While it is important to acknowledge the concerns raised about both, it is also crucial to highlight the ongoing advancements in these technologies. Continuous research and development efforts are improving the efficacy of CCUS, ensuring a higher percentage of carbon is captured and stored. There are already existing markets for carbon sequestration – such as Enhanced Oil Recovery (EOR) where CO2 gas is injected into a well and can act as a solvent to release oil and gas from rock strata and flush them to the well head. Additional CCUS technologies are being developed that don’t contribute to increases in oil & gas production – such as permanent underground sequestration, utilizing CO2 as a feedstock for manufacturing synthetic fuels, permanently capturing CO2 as a solid in concrete materials, plastics/chemicals manufacturing from CO2 feedstocks, solid precipitation as calcium carbonite, and microalgae production. All these technologies are still fairly new, but CCUS technology improvement is a must if humanity is to reach Net Zero by 2050. [15]

fugitive methane emissions contribute to minimizing environmental impact. Many detractors of blue hydrogen production rightly point out that methane itself is a potent greenhouse gas – and the benefits of blue hydrogen production can be squandered if enough methane is released during its production, storage, and transportation. [1] Technologies enabling industry to monitor and correct these emissions, as well as government monitoring for regulatory & compliance purposes, will be crucial. It is estimated that at least 50% of global fugitive methane emissions from natural gas activities could be saved by using technologies and approaches that would pay for themselves just based on the recovery of the methane. [16] Without any other incentives – if provided with the right tools and technologies - there is economic motivation for industry to recapture this lost methane. Other technologies have already led to drastic improvements in monitoring fugitive emissions, including optical gas imaging cameras, aerial monitoring (aircraft, methane balloon, and drone/UAV), and satellite monitoring. [17] These technologies can and should be leveraged to implement transparency and reporting requirements for methane emissions, and potentially future taxes/quotas to ensure proper incentives for methane emissions reduction. Since fugitive methane emissions are one of the largest arguments against blue hydrogen, any improvements in this area increases the argument for conversion.

Reassessing Global Warming Potential (GWP) Time Horizon:

One aspect often overlooked in the conversation surrounding blue hydrogen is the choice of the time horizon for GWP, or Global Warming Potential, assessment. GWP allows emission impacts from different gases to be standardized to an “equivalent CO2” unit. Many of the recent analyses of blue hydrogen focus on a 20-year GWP calculation rather than the standard 100- year. This, combined with assumptions like 3.5% fugitive emissions, immediately put any technology leveraging natural gas at a significant disadvantage. Methane, a potent but short-lived greenhouse gas, does not linger in the atmosphere as long as carbon dioxide – therefore the shorter time horizon stacks the deck significantly against it.

There are two important reasons to look at a 100-year GWP instead – or to at least consider both. First, it is the most well-known and widely used metric - baked into policies, international agreements, and greenhouse gas reporting requirements. [18] It is therefore most likely to be utilized in any future legislation around carbon control. Second, 100 years is a much more reasonable time frame for humanity to achieve a fully carbon neutral/negative energy and manufacturing system than 20 years. Despite many countries and companies pledging a goal of Net Zero by 2050, humanity is currently not on course to meet this objective. [19] A 100-year GWP will therefore be better able to capture the effects of methane produced today over the course of humanity’s path to a carbon neutral future.

Evaluations of blue vs. grey vs. green hydrogen that a) do not consider the potential (and likely) future fugitive methane emissions reductions, and b) look only at a 20-year GWP analysis of methane, are stacking the deck against any technology that leverages natural gas. This includes 99% of existing hydrogen manufacturing capacity today, which cannot be easily or quickly converted to renewable H2 production.

Figure 4. GWP Comparison for Methane

Renewable and Low-Carbon Driving Forces:

One final often-overlooked advantage of blue hydrogen lies in its flexibility regarding energy sources. As described above – new renewable and low-carbon energy assets are currently put to better use offsetting existing electricity generation than offsetting hydrogen production via electrolysis – but this will not always be the case. As the global electricity grid is decarbonized over the coming decades, eventually hydrogen production will be the lowest hanging fruit, and it will make sense to apply low-carbon electricity to offset current production. With blue hydrogen, there are areas where this new renewable electricity can be used, including energy requirements for separating and purifying captured CO2, and CO2 compression. This further improves the CO2 footprint of blue hydrogen over grey, giving us additional time to build up electrolysis assets and expertise to continue to decarbonize the hydrogen market.

Conclusion:

In the pursuit of a sustainable future, it is crucial that we avoid dismissing viable solutions without a comprehensive assessment. Blue hydrogen, when produced with improved CCUS and fugitive methane emission technologies, coupled with a careful consideration of GWP values and the use of renewable or low-carbon energy sources, can serve as a vital stepping-stone in our transition to a low-carbon economy. While not a panacea, blue hydrogen contributes meaningfully to our collective efforts to mitigate climate change while electrolysis capacity and renewable energy resources continue to grow. As we navigate the complex terrain of the energy transition, a balanced and nuanced approach that considers the realities of current industries, technological advancements, and the urgency of the climate crisis will be key to shaping a sustainable hydrogen future.

References:

[1] How green is blue hydrogen? Howarth RW, Jacobson MZ. 2021, Energy Sci Eng., pp. 1676-1687.

[2] International Energy Agency. Global Hydrogen Review 2022. 2022.

[3] Badamasi, Hamza. earth.org. [Online] December 2, 2020. [Cited: January 14, 2023.] https://earth.org/data_visualization/the-coal-to-naturalgas-transition-is-saving-lives/.

[4] U.S. Energy Information Administration. Today in Energy. eia.gov. [Online] August 5, 2020. [Cited: Jan 24, 2024.] https://www.eia.gov/todayinenergy/detail.php?id=44636# :~:text=According%20to%20data%20from%20the,by%20na tural%20gas%2Dfired%20plants..

[5] Comparative assessment of blue hydrogen from steam methane reforming, autothermal reforming, and natural gas decomposition technologies for natural gas-producing regions. A.O. Oni, K. Anaya, T. Giwa, G. Di Lullo, A. Kumar. 115245, s.l. : Energy Conversion and Management, 2022, Vol. 254. ISSN 0196-8904.

[6] Shell. shell.com. Blue Hydrogen Production. [Online] 2023. [Cited: Jan 24, 2024.] https://www.shell.com/business-customers/catalyststechnologies/licensed-technologies/refinerytechnology/shell-blue-hydrogen-process.html.

[7] Hockey, Mike. Honeywell Performance Materials and Technologies. pmt.honeywell.com. [Online] [Cited: January 24, 2024.] https://pmt.honeywell.com/us/en/aboutpmt/newsroom/press-release/2022/05/cvr-energysubsidiary-selects-honeywell-for-a-lower-carbon-hydrogenstudy-at-coffeyvillesite#:~:text=Depending%20on%20the%20inlet%20gas,incr easing%20high%2Dpurity%20hydrogen%20recov.

[8] Blain, Loz. Record-breaking hydrogen electrolyzer claims 95% efficiency. [Online] New Atlas, March 16, 2022. [Cited: January 14, 2024.] https://newatlas.com/energy/hysataefficient-hydrogen-electrolysis/.

[9] IEA. Comparison of the emissions intensity of different hydrogen production routes. iea.org. [Online] June 29, 2023. [Cited: January 14, 2024.] https://www.iea.org/dataand-statistics/charts/comparison-of-the-emissionsintensity-of-different-hydrogen-production-routes-2021.

[10] IEA. Renewable Energy Market Update - June 2023. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energy-marketupdate-june-2023/executive-summary.

[11] Ember. ember-climate.org. Yearly electricity data. [Online] January 23, 2024. [Cited: January 24, 2024.] https://ember-climate.org/data-catalogue/yearlyelectricity-data/.

[12] IEA. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energymarket-update-june-2023/executive-summary.

[13] IEA. iea.org. Towards hydrogen definitions based on their emissions intensity. [Online] 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/towards-hydrogendefinitions-based-on-their-emissions-intensity/executivesummary.

[14] Global Energy & CO2 Status Report 2019. IEA. Paris : IEA, 2019.

[15] Lebling, Katie, et al. World Resources Institute. [Online] November 13, 2023. [Cited: January 14, 2024.] https://www.wri.org/insights/carbon-capturetechnology#:~:text=The%202023%20IEA%20Roadmap%20 to,mitigation%20of%20energy%20sector%20emissions..

[16] European Commission - Fugitive Methane Emissions. commission.europa.eu. [Online] June 2020. [Cited: January 14, 2024.] https://commission.europa.eu/system/files/2020- 06/speaker_intervention_- _european_university_institute.pdf.

[17] Exxonmobil press release. ExxonMobil field testing new comprehensive methane monitoring technologies. corporate.exxonmobil.com. [Online] April 9, 2020. [Cited: January 14, 2024.] https://corporate.exxonmobil.com/news/newsreleases/2020/0409_exxonmobil-field-testing-newcomprehensive-methane-monitoring-technologies.

[18] Ocko, Ilissa B and Hamburg, Steven P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. [Online] July 20, 2022. [Cited: January 14, 2024.] https://doi.org/10.5194/acp-22-9349-2022. 9349-9368.

[19] United Nations. un.org. For a livable climate: Net-zero commitments must be backed by credible action. [Online] [Cited: January 24, 2024.] https://www.un.org/en/climatechange/net-zerocoalition#:~:text=Are%20we%20on%20track%20to,short% 20of%20what%20is%20required..

As the world grapples with the need to transition to low-carbon energy sources, the debate over the viability of blue hydrogen – hydrogen gas produced through steam methane reforming (SMR) combined with carbon capture and storage (CCUS) - has intensified. Recent critiques have cast doubt on the environmental benefits of blue hydrogen, with some going as far as to argue that it is more carbonintensive than its grey hydrogen counterpart (SMR with no CCUS). [1] However, a closer examination of key factors reveals that dismissing the benefits of blue hydrogen would be premature. In simpler terms – don’t throw the baby out with the bathwater.

Understanding Grey Hydrogen's Current Role:

Grey hydrogen, produced through conventional SMR without CCUS, plays a massive role in various industries - including oil refining, ammonia & methanol production, steelmaking, and concrete production. In 2022, these industries globally required over 94 Mt of hydrogen product, and less than 1% of this H2 was produced as low-emission hydrogen. This low-emission hydrogen production needs to grow more than 100x by 2030 to be in line with the “Net Zero Emissions by 2050” (NZE)scenario. All told, existing global hydrogen production accounts for between 920-1060 Mt of CO2 emissions per year, or roughly the same carbon footprint as the entire global aviation industry. [2]

Figure 1. Hydrogen Usage in Different Industries

The stark reality is that these sectors are unlikely to transition rapidly to fully renewable hydrogen. There is significant infrastructure dedicated to grey hydrogen that would have no use as we transition to electrolysis/green hydrogen production methods. It is much more feasible in the near term (2-3 decades) to combine these existing grey hydrogen assets with CCUS technology – converting them from grey to blue hydrogen producers - to drastically reduce the carbon emissions from current hydrogen needs. This is similar to what has been done with coal power generation across the globe – leveraging existing boiler assets and converting them to natural gas or utilizing CCUS technologies to directly capture CO2 from flue gas streams – to reduce the CO2 footprint of that electricity source, rather than just idling/abandoning the existing equipment. [3] In the US alone, 121 coalfired power plants were repurposed to burn other types of fuels from 2011 to 2019 – 103 of which went to natural gas. [4]

A blue hydrogen strategy of just 60% CO2 capture would result in up to 640 Mt of carbon emission abatement – a capture percentage that has already been demonstrated at commercial scale and requires only pre-combustion CCUS technology – equivalent to the CO2 footprint of over 138 million passenger vehicles. An argument can be made that up to 92% CO2 capture rates are possible when post combustion capture of the flue gas is included [5], and up to 99% is possible with newer technologies like autothermal reforming which eliminates the flue gas stream. [6; 7]

The Electrolysis Challenge:

Many of the detractors of blue hydrogen are proponents of transitioning directly to green 31.8 26.24 15.9 5.3 Ammonia Refining Methanol Steelmaking H2 used globally (Mt) hydrogen. While green hydrogen - produced through electrolysis of water using renewable energy - is an appealing prospect, scaling up electrolysis to meet global hydrogen demand poses considerable challenges. The sheer magnitude of current hydrogen usage in multiple industries and the difficulty of rapidly replacing existing grey hydrogen infrastructure make blue hydrogen a more pragmatic choice in the near term.

Electrolysis requires ~50 kWh of electricity to produce a single kg of hydrogen. [8] For the hydrogen produced from electrolysis to be “green”, this 50 kWh/kg must come directly from renewable energy sources – like wind, solar, or hydro. By comparison, the SMR reaction is endothermic and requires roughly the same energy input (44.5 kWh/kg) [9], but this energy can come from directly burning a portion of the natural gas feed to the reactor. Little to no additional electricity production is needed. This energy requirement does not change significantly when converting from grey to blue hydrogen either. To implement 60% CO2 capture, the energy required per kg of H2 produced only increases by 1-2%. For 93% capture, we see a 10-12% increase in energy required, though this is still below the energy threshold for electrolysis produced H2. [9]

To demonstrate how far we are from 100% replacement of today’s hydrogen needs with green hydrogen, we can look at global energy production - both total and renewable:

Figure 2. Global Energy Production, Renewables, and Required Energy for Green Hydrogen [7; 8]

According to the International Energy Agency (IEA), global renewable energy capacity will be roughly 4500 TW for 2024. [10] Even if 100% of global renewable energy was redirected to producing green hydrogen, we would still be 200 TW short – and that is without considering the significant increases in global hydrogen demand that will be needed to decarbonize other hard to-abate industries such as steel, aviation, and long-haul transportation.

As the final point to the electrolysis challenge: globally we are currently adding between 300- 500 TW of renewable energy capacity each year. [12] For these new renewable energy sources, will replacing existing grey H2 generation with renewable electrolysis be the largest carbon abatement opportunity? The carbon footprint of each kg of hydrogen produced today is roughly 11.3 kg CO2 equivalent. [13] Based on electrolysis energy requirements, each kWh of renewable power towards green hydrogen therefore abates ~230 g CO2eq. If we compare this to the global average for all energy production, we can see that this additional renewable green capacity is better applied to offsetting existing electricity generation than it would be applied to replacing grey/blue H2 production [9; 14]:

Figure 3. Potential Abatement per kWh Renewables

Based on this data – the best use of additional renewable capacity from a carbon abatement standpoint would be to tackle other existing heavy carbon emitting power generation prior to replacing grey H2 production. This is not to say that grey hydrogen production does not need to be tackled – only that it would be more prudent to convert existing grey assets to blue, while utilizing our current and future renewable assets to offsetting other heavier CO2 sources.

Advancements in CCUS and Fugitive Methane Emission Technologies:

Arguments against blue hydrogen point out the large impacts of both fugitive methane emissions (natural gas leaks from production to utilization), as well as the unpredictability of CCUS storage methods. While it is important to acknowledge the concerns raised about both, it is also crucial to highlight the ongoing advancements in these technologies. Continuous research and development efforts are improving the efficacy of CCUS, ensuring a higher percentage of carbon is captured and stored. There are already existing markets for carbon sequestration – such as Enhanced Oil Recovery (EOR) where CO2 gas is injected into a well and can act as a solvent to release oil and gas from rock strata and flush them to the well head. Additional CCUS technologies are being developed that don’t contribute to increases in oil & gas production – such as permanent underground sequestration, utilizing CO2 as a feedstock for manufacturing synthetic fuels, permanently capturing CO2 as a solid in concrete materials, plastics/chemicals manufacturing from CO2 feedstocks, solid precipitation as calcium carbonite, and microalgae production. All these technologies are still fairly new, but CCUS technology improvement is a must if humanity is to reach Net Zero by 2050. [15]

fugitive methane emissions contribute to minimizing environmental impact. Many detractors of blue hydrogen production rightly point out that methane itself is a potent greenhouse gas – and the benefits of blue hydrogen production can be squandered if enough methane is released during its production, storage, and transportation. [1] Technologies enabling industry to monitor and correct these emissions, as well as government monitoring for regulatory & compliance purposes, will be crucial. It is estimated that at least 50% of global fugitive methane emissions from natural gas activities could be saved by using technologies and approaches that would pay for themselves just based on the recovery of the methane. [16] Without any other incentives – if provided with the right tools and technologies - there is economic motivation for industry to recapture this lost methane. Other technologies have already led to drastic improvements in monitoring fugitive emissions, including optical gas imaging cameras, aerial monitoring (aircraft, methane balloon, and drone/UAV), and satellite monitoring. [17] These technologies can and should be leveraged to implement transparency and reporting requirements for methane emissions, and potentially future taxes/quotas to ensure proper incentives for methane emissions reduction. Since fugitive methane emissions are one of the largest arguments against blue hydrogen, any improvements in this area increases the argument for conversion.

Reassessing Global Warming Potential (GWP) Time Horizon:

One aspect often overlooked in the conversation surrounding blue hydrogen is the choice of the time horizon for GWP, or Global Warming Potential, assessment. GWP allows emission impacts from different gases to be standardized to an “equivalent CO2” unit. Many of the recent analyses of blue hydrogen focus on a 20-year GWP calculation rather than the standard 100- year. This, combined with assumptions like 3.5% fugitive emissions, immediately put any technology leveraging natural gas at a significant disadvantage. Methane, a potent but short-lived greenhouse gas, does not linger in the atmosphere as long as carbon dioxide – therefore the shorter time horizon stacks the deck significantly against it.

There are two important reasons to look at a 100-year GWP instead – or to at least consider both. First, it is the most well-known and widely used metric - baked into policies, international agreements, and greenhouse gas reporting requirements. [18] It is therefore most likely to be utilized in any future legislation around carbon control. Second, 100 years is a much more reasonable time frame for humanity to achieve a fully carbon neutral/negative energy and manufacturing system than 20 years. Despite many countries and companies pledging a goal of Net Zero by 2050, humanity is currently not on course to meet this objective. [19] A 100-year GWP will therefore be better able to capture the effects of methane produced today over the course of humanity’s path to a carbon neutral future.

Evaluations of blue vs. grey vs. green hydrogen that a) do not consider the potential (and likely) future fugitive methane emissions reductions, and b) look only at a 20-year GWP analysis of methane, are stacking the deck against any technology that leverages natural gas. This includes 99% of existing hydrogen manufacturing capacity today, which cannot be easily or quickly converted to renewable H2 production.

Figure 4. GWP Comparison for Methane

Renewable and Low-Carbon Driving Forces:

One final often-overlooked advantage of blue hydrogen lies in its flexibility regarding energy sources. As described above – new renewable and low-carbon energy assets are currently put to better use offsetting existing electricity generation than offsetting hydrogen production via electrolysis – but this will not always be the case. As the global electricity grid is decarbonized over the coming decades, eventually hydrogen production will be the lowest hanging fruit, and it will make sense to apply low-carbon electricity to offset current production. With blue hydrogen, there are areas where this new renewable electricity can be used, including energy requirements for separating and purifying captured CO2, and CO2 compression. This further improves the CO2 footprint of blue hydrogen over grey, giving us additional time to build up electrolysis assets and expertise to continue to decarbonize the hydrogen market.

Conclusion:

In the pursuit of a sustainable future, it is crucial that we avoid dismissing viable solutions without a comprehensive assessment. Blue hydrogen, when produced with improved CCUS and fugitive methane emission technologies, coupled with a careful consideration of GWP values and the use of renewable or low-carbon energy sources, can serve as a vital stepping-stone in our transition to a low-carbon economy. While not a panacea, blue hydrogen contributes meaningfully to our collective efforts to mitigate climate change while electrolysis capacity and renewable energy resources continue to grow. As we navigate the complex terrain of the energy transition, a balanced and nuanced approach that considers the realities of current industries, technological advancements, and the urgency of the climate crisis will be key to shaping a sustainable hydrogen future.

References:

[1] How green is blue hydrogen? Howarth RW, Jacobson MZ. 2021, Energy Sci Eng., pp. 1676-1687.

[2] International Energy Agency. Global Hydrogen Review 2022. 2022.

[3] Badamasi, Hamza. earth.org. [Online] December 2, 2020. [Cited: January 14, 2023.] https://earth.org/data_visualization/the-coal-to-naturalgas-transition-is-saving-lives/.

[4] U.S. Energy Information Administration. Today in Energy. eia.gov. [Online] August 5, 2020. [Cited: Jan 24, 2024.] https://www.eia.gov/todayinenergy/detail.php?id=44636# :~:text=According%20to%20data%20from%20the,by%20na tural%20gas%2Dfired%20plants..

[5] Comparative assessment of blue hydrogen from steam methane reforming, autothermal reforming, and natural gas decomposition technologies for natural gas-producing regions. A.O. Oni, K. Anaya, T. Giwa, G. Di Lullo, A. Kumar. 115245, s.l. : Energy Conversion and Management, 2022, Vol. 254. ISSN 0196-8904.

[6] Shell. shell.com. Blue Hydrogen Production. [Online] 2023. [Cited: Jan 24, 2024.] https://www.shell.com/business-customers/catalyststechnologies/licensed-technologies/refinerytechnology/shell-blue-hydrogen-process.html.

[7] Hockey, Mike. Honeywell Performance Materials and Technologies. pmt.honeywell.com. [Online] [Cited: January 24, 2024.] https://pmt.honeywell.com/us/en/aboutpmt/newsroom/press-release/2022/05/cvr-energysubsidiary-selects-honeywell-for-a-lower-carbon-hydrogenstudy-at-coffeyvillesite#:~:text=Depending%20on%20the%20inlet%20gas,incr easing%20high%2Dpurity%20hydrogen%20recov.

[8] Blain, Loz. Record-breaking hydrogen electrolyzer claims 95% efficiency. [Online] New Atlas, March 16, 2022. [Cited: January 14, 2024.] https://newatlas.com/energy/hysataefficient-hydrogen-electrolysis/.

[9] IEA. Comparison of the emissions intensity of different hydrogen production routes. iea.org. [Online] June 29, 2023. [Cited: January 14, 2024.] https://www.iea.org/dataand-statistics/charts/comparison-of-the-emissionsintensity-of-different-hydrogen-production-routes-2021.

[10] IEA. Renewable Energy Market Update - June 2023. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energy-marketupdate-june-2023/executive-summary.

[11] Ember. ember-climate.org. Yearly electricity data. [Online] January 23, 2024. [Cited: January 24, 2024.] https://ember-climate.org/data-catalogue/yearlyelectricity-data/.

[12] IEA. iea.org. [Online] June 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/renewable-energymarket-update-june-2023/executive-summary.

[13] IEA. iea.org. Towards hydrogen definitions based on their emissions intensity. [Online] 2023. [Cited: January 14, 2024.] https://www.iea.org/reports/towards-hydrogendefinitions-based-on-their-emissions-intensity/executivesummary.

[14] Global Energy & CO2 Status Report 2019. IEA. Paris : IEA, 2019.

[15] Lebling, Katie, et al. World Resources Institute. [Online] November 13, 2023. [Cited: January 14, 2024.] https://www.wri.org/insights/carbon-capturetechnology#:~:text=The%202023%20IEA%20Roadmap%20 to,mitigation%20of%20energy%20sector%20emissions..

[16] European Commission - Fugitive Methane Emissions. commission.europa.eu. [Online] June 2020. [Cited: January 14, 2024.] https://commission.europa.eu/system/files/2020- 06/speaker_intervention_- _european_university_institute.pdf.

[17] Exxonmobil press release. ExxonMobil field testing new comprehensive methane monitoring technologies. corporate.exxonmobil.com. [Online] April 9, 2020. [Cited: January 14, 2024.] https://corporate.exxonmobil.com/news/newsreleases/2020/0409_exxonmobil-field-testing-newcomprehensive-methane-monitoring-technologies.

[18] Ocko, Ilissa B and Hamburg, Steven P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. [Online] July 20, 2022. [Cited: January 14, 2024.] https://doi.org/10.5194/acp-22-9349-2022. 9349-9368.

[19] United Nations. un.org. For a livable climate: Net-zero commitments must be backed by credible action. [Online] [Cited: January 24, 2024.] https://www.un.org/en/climatechange/net-zerocoalition#:~:text=Are%20we%20on%20track%20to,short% 20of%20what%20is%20required..

About DiviGas:

DiviGas is a start-up in the energy industry, we have invented a radically new process for manufacturing next-generation membranes for hydrogen separation and purification.

We have an acknowledged bias towards gas purification but this expertise is precisely why we have a special point of view on these industrial topics. At the time of writing we are not paid or financed by large oil and gas companies and our unambiguous objective as a company is to promote and advance technology for decarbonization and solving climate change.